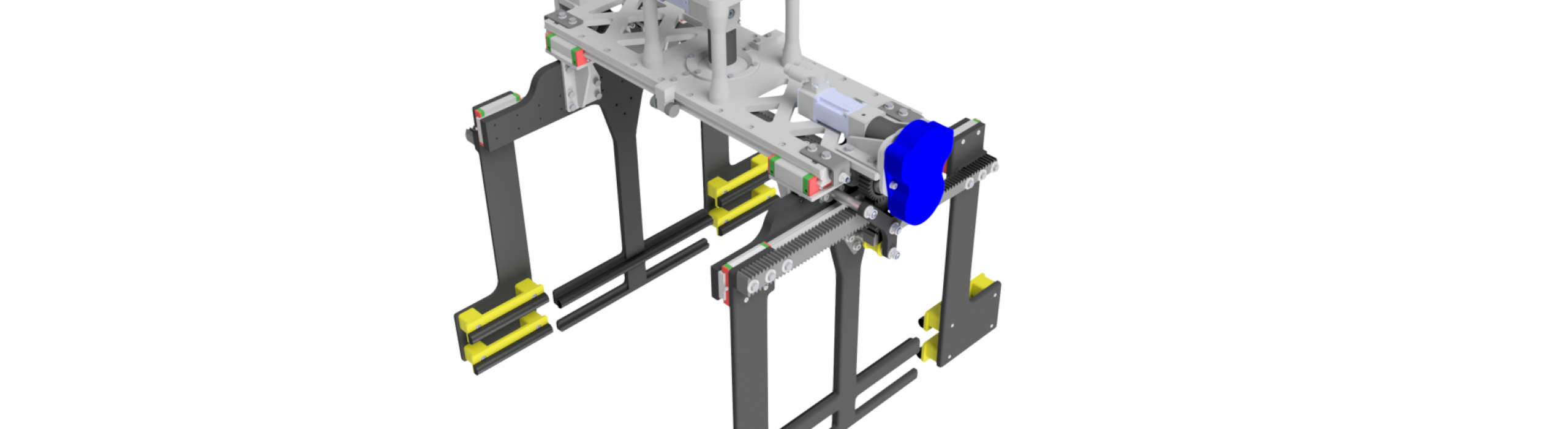

Manipulator with Variable-Geometry Gripper

The variable-geometry gripper developed by Mako (patent pending) represents a significant evolution compared to traditional gripping systems used in food & beverage and packaging production lines.

Unlike conventional grippers—whose length must be defined during the design phase and therefore remains limited to specific formats—the Mako gripper can automatically adjust its configuration in real time based on the format being handled.

This ability to adapt the gripper’s length not only reduces the number of manipulations required but also allows for a decrease in the spacing between groups of items that need to be handled with separate grips.

As a result, the layer formation table can operate at a lower speed while increasing the performance of the Delta robot. Since the robot covers a shorter distance, the manipulation time is significantly reduced, enabling a higher number of manipulations per minute.

This feature optimizes product arrangement on the pallet, improving the overall efficiency of the packaging cycle and contributing to an increase of up to 50% in overall line performance compared to both cartesian and non-cartesian manipulators equipped with conventional tools.

The mechatronic architecture of the gripper ensures high rigidity, precise positioning, and repeatability, even when handling variable loads of up to 54 kg.

The Mako gripper also offers greater operational flexibility and reduced format changeover times, eliminating the need to replace tools or mechanical adapters.

From a maintenance standpoint, the absence of belts and traditional transmission components significantly reduces periodic servicing and increases the overall reliability of the system.